![[IMAGE]](http://www.darrylsgarage.com/912/912dream.jpg)

![[IMAGE]](http://www.darrylsgarage.com/912/912dream.jpg)

![[IMAGE]](http://www.darrylsgarage.com/912/912-rust9.jpg)

Entry: 2/16/06 - Today I attacked the rear half of the cabin floor, cutting out the floorpan between the left and right longitudinals and inside the center tunnel. As you can see from the picture, remarkably little rot on the flanges and inside the center tunnel. The extreme rot in the floor of the longitudinal channels under the rear torsion bar tube on both sides is also clearly visible. This explains why I'm replacing the rear floor first, as the "foundation" panel because those spotweld flanges under the torsion bars of the floorpan have rotted away and I need something to measure from to fabricate their patch panels.

![[IMAGE]](http://www.darrylsgarage.com/912/912flor0.jpg)

In the second photo, I placed the rotten sections cut from the car on top of the new replacement pressing to show the amount of sheetmetal still needing removal between the inner channel flange and the outer rocker panels. One good thing is the inner and outer rocker panels are to be replaced all new metal so there really is isn't much more flange trimming required, only the inside flange needs to be cut-down to a ¾" wide strip like the one on the center tunnel channel. Between cutting sessions I welded in new wiring harness tabs across the front of the spare tire well and cleaned-up the passenger-side headlight conduit and painted it. I'll hold-off on any more nose section photos until it's ready for its unveiling after the Wurth underseal is applied.

![[IMAGE]](http://www.darrylsgarage.com/912/912flor1.jpg)

Entry: 9/17/06 - Today's task was cutting the forward section of floorpan out of the center "hump" and cleaning-up the flanges to prepare them for welding the new floorpan pressings to. I purchased a new tool over the summer, a cheap $40 Harbor Freight pneumatic body saw that really made trimming down the flanges much easier. I use my 4½" grinder with a cut-off wheel for making the rough cuts but the pneumatic body saw allowed me to trim the flanges with greater precision. With the entire center "hump" open it is easy to access all the controls and cables. I am very pleased with how clean and sound the sheetmetal is inside the center channel but noticed all the nylon shifter and throttle cable bushings are severely worn. I also noticed one of the parking brake tubes has broken free from the weld that holds it to the channel so I'll have to tack that into place before closing it up with the new floorpans. What better time to replace the speedometer cable, brake line and various nylon bushings when I can easily access them from the bottom. I left the leading edge of the old floorpan in place so I can measure and mark-off the location of the threaded stud plates that hold down the plywood foot rests. I also cleaned-up the passenger side inner longitudinal panel's flange and figured out where I'm going to have to cut out rusted sections to patch it.

![[IMAGE]](http://www.darrylsgarage.com/912/912flor2.jpg)

Entry: 9/26/06 - After marking where the front edge of the new floorpan pressing hits the old floorpan last night, today's task was to trim the excess old floorpan out and prepare the pinch weld flange on the back of the wheelwell for the new floor. I decided to allow an extra ½" overlap on the old floorpan to allow for a nice wide lap joint that I'll run a MIG weld bead down on both sides. There is a reinforced area under the two captive nuts for the gas pedal, which I decided to trim around and leave in place. I'll integrate that into the new floorpan pressing somehow, the metal is perfect and it would be a shame to lose the detail.

![[IMAGE]](http://www.darrylsgarage.com/912/912flor5.jpg)

The passenger side footboard retaining bracket was cut out of the old floorpan, media blasted and carefully measured and spotwelded to the new floorpan pressing. I also drilled all the drain holes that run down the floor of the center channel and rescued the original rubber plugs from the old floorpans.

![[IMAGE]](http://www.darrylsgarage.com/912/912flor4.jpg)

Entry: 10/4/06 - Now for the million dollar question, "Do all the new spotweld flanges I've added line up with the new floor pan pressings, especially under those rear torsion bar tubes?" Well, to find that out I needed to use every one of my Vise-Grip pliers and slowly work the replacement floor pans into position. The answer to the million dollar question? YEAH BABY! PERFECT-O!!!

![[IMAGE]](http://www.darrylsgarage.com/912/912flor6.jpg)

I still need to figure out how I'm going to knit the front seam of the front floor pan pressing into the existing pedal mounting points and such and today's fitting allowed me to mark-off the precise locations of those mounting points. Otherwise the rest of the flanges around the perimeter of the floorpan are very, very close! I can really picture how this is going to look all welded in and covered with a 1/8" thick coating of sound deadener on the cabin side and thick splatter coat of undercoating on the outside. I don't think anybody will be able to detect the repair without having the subtle differences in the replacement pressings pointed out to them, as is the intent.

![[IMAGE]](http://www.darrylsgarage.com/912/912flor7.jpg)

Entry: 10/7/06 - Today I got all the rear suspension stuff sorted out and bolted in, I put the road wheels back on the rear axle and lowered the car off the jacks so I could use them to push the rear floor into its highest position. I found a really great picture (on eBay) of the finished rear floor and longitudinal panel flanges the way they came from the factory so I can determine how much of the excess flange I need to cut off and roll over on my replacement ones. I think I can make mine look just like factory, no worries!

![[IMAGE]](http://www.darrylsgarage.com/912/912exam1.jpg)

![[IMAGE]](http://www.darrylsgarage.com/912/912flor8.jpg)

I have quite a bit more metal to remove from the rear bulkhead flange at the back end of the center hump before the new floorpan can be pushed high enough to touch the spotweld flanges along the inside perimeter. Just one of the dozens of details that need to be worked-out before I can weld the floor in and all very exciting to be at this point and picturing that floor finished.

Entry: 10/9/06 - Today it was time for some "spelunking" in the center tunnel. I carefully removed the hand brake and cables, shifter and throttle linkage, and speedometer cable to see what kind of condition they are in. I made a big order to Stoddards to get the rest of the new bushings, rubber boots and a new brake line kit to complete the job. I could probably do without replacing the brake lines but what better time to replace the one inside the center tunnel than now with the floor out. The fuel line looks to be in perfect shape so that will be left as is. I turned my attention to how I'm going to attach the front edge of the new front floorpan, saving the original reinforcing plate for attaching the base of the gas pedal. As you can see in the following photo, I used red-oxide primer to "ghost" where the new floorpan will be slipped on top of the gas pedal reinforcing plate and plug-welded to the old one through the holes I punched there. The two large holes are for accessing the captive nuts to hold the foot pedal down. I also punched plug-weld holes all the way across the front lip of the new floorpan for attaching it to the ½" overlap I left in the original floorpan. I decided plug welds would be easiest from the bottom side because I can use my screw jacks to press the new floorpan sheetmetal up to the old floor, which has already been stripped and primed with zinc 3M Weld-thru Primer.

![[IMAGE]](http://www.darrylsgarage.com/912/912flor9.jpg)

Working out the details of the rear edge of the rear floorpan where the rear bulkhead of the center tunnel attaches was fairly easy to figure out. The original factory weld was a bead along the edge of a flange on the rear tunnel bulkhead pointing rearward where the bulkhead and floorpan sheetmetal meet. All I had to do was cut away the weld and the original floorpan sheetmetal peeled away to provide a nice clean edge to align the new floorpan sheetmetal to. I'll have to cut the excess lip off the new pressing to make it easier to form to the contour of the rear bulkhead under the shift rod hole. Removing all the cables and throttle rod is required so I can have access to that lower edge with my MIG welder. I don't think I need to remove the heater control cables since they sit high enough to be out of the way. I have a little surface rust to spot sandblast on the last 10" or so of the inside of the center tunnel spotweld flanges where water pooled but was caught before it could weaken the sheet metal there.

![[IMAGE]](http://www.darrylsgarage.com/912/912flora.jpg)

The final task for the day was to cut down all the new pinchweld flanges around the perimeter of the new outer longitudinal sheetmetal to its final size. Once cut down, plug-weld holes were punched every ¾" (the same distance apart as the factory spot welds) along the perimeter pinchweld flange and the inside longitudinal panel to floorpan flange. I plan to position the new floorpans so the top edge of the flanges line up, make the plug-welds and then cut off the excess sheetmetal from the bottom edge of the floorpan flanges. I may or may not run a solid bead of weld along the bottom edge before I cut off the excess, depending on how solid the pans feel with the plug-welds.

![[IMAGE]](http://www.darrylsgarage.com/912/912RRKRr.jpg)

Entry: 10/10/06 -Today's efforts focused on preparing the spot weld flanges on each side of the center tunnel. I had been considering leaving the extra layer of original floor spotwelded to the flange but the double thickness of metal made it impossible to punch with my pneumatic plug-weld punching tool. It also left the possibility of rust lurking between the layers of old spotweld flange which isn't acceptable so I decided to bite the bullet and remove it. Peeling back the old floorpan steel spot welded to the flange took several hours but when it was all removed, I punched the plug-weld holes with my tool and all was good. I also prepped the flange on the interior wall of the rear floor bulkhead and punched the plug-weld holes there as well. Once all traces of surface rust was removed from the bottom side of the center tunnel spot weld flange, surface rust inside of the tunnel and asphalt based undercoating from the rear side of the rear floor bulkhead, I sprayed it with a coat of zinc 3M Weld-thru Primer and declared it ready to weld. The longitudinal flanges need the bottom sides cleaned and primed but I ran out of primer so that will have to wait.

![[IMAGE]](http://www.darrylsgarage.com/912/912florb.jpg)

Now for the fun stuff, final fitting of the front floorpan pressing. I little trimming up front around the pedal area and then forming it with a blunt-ended chisel attachment for my air hammer and it fit in very nicely. Any remaining gap fitting around the pedal area can wait until after the plug-welds are done and I can form and knit the new pressing into the old for a more finished look. As it sits right now, all the spotweld flanges mate perfectly and when dressed to expose the bare metal at all contact points, will be ready for welding. I need to complete the right jack plate installation before starting with the rear floorpan fitting, so that will be the next task.

![[IMAGE]](http://www.darrylsgarage.com/912/912florc.jpg)

Entry: 10/12/06 - Today's efforts got off to a slow start. I began the day with doing some media blasting and discovered that my dust collector was plugged because my media is getting too dusty from too many trips through the blaster. The first couple hours were spent disassembling the dust collector and washing out the filter bag with a garden hose. I'll be emptying the old media from the cabinet and getting new stuff on Monday. After that "housekeeping" task was completed, I welded in the left side jack tube to the anchor point on the inner longitudinal panel and began fitting the rear floorpan pressing. After hours of very hard labor, the rear floorpan pressing has been coerced by hand and air hammer into the final position and the flanges all formed so the 90°bends align like a 'T' on the pinch weld flanges along the rockerpanels and the flanges make uniform contact along the floor flanges. I'm still waiting on welding the pans back in until my Stoddards order with the new parts for inside the tunnel arrives and in the meantime will be wire-brushing all the flanges and zinc priming them in preparation for welding day. Tomorrow is a big day for me, I finally get to take my '63 VW Beetle Cabriolet in to have a new top custom made by Steve Shepp, one of the best German car trimmers on the West Coast! It's taken a year to get this spot in the long line that has formed in front of his door and his last project was a hand-build 1953 Graber Bentley roadster insured for over a million bucks!

![[IMAGE]](http://www.darrylsgarage.com/912/912RFLR1.jpg)

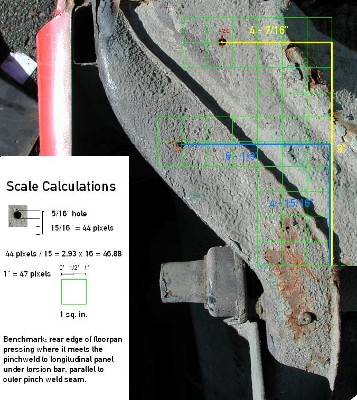

Entry: 10/13/06 - There are some factory drain / access holes in the floorpan and longitudinal panels that are plugged with the same little rubber plugs as those used in the floor of the center tunnel. Since rust had obliterated where they were on my original sheetmetal, some investigation was required and luckily, a few months back, I snapped a digital photo of an intact '66 912 rear clip resting on its top at my friend Jack Morris' boneyard behind his shop, Wolfsburg Motorwerks in Ballard. Some careful manipulation in Photoshop and plotting using pixels as the measuring unit, I was able to plot their precise locations in inches. Tomorrow, I'll drill those holes, and the 3 others that run down the side of each inner rocker panel so I can access those body cavities with rust proofing materials once the floorpans are all welded in. Double-click on the following photo to see the full-size (readable) hole location map.

Entry: 10/14/06 - The front and rear floorpan pressings have all the pre-welding fitting and trimming done and as you can see in the photo below, the center seam mates exactly as it will once installed in the car, rear floorpan first. Today I also drilled all the factory drain / access holes that will be used to rust-proof the longitudinal body cavities once the welds have been completed. It was a very good thing to do the drilling while I could still have access to the inside of the longitudinal channel and shield the heater tube from punctures with the drill. I double-checked the hole size on the inner rocker panel access holes and discovered they are slightly smaller than the holes in the center tunnel and I adjusted the size accordingly. I've made significant progress on wire brushing the remaining plug-weld flanges in preparation for welding. Next I need to repair the broken weld on the left parking brake tube inside the center tunnel. I'm taking my time and trying to anticipate everything that needs to be considered while waiting for the Stoddard's part order and the actual welding of the pans... no reason to be in a rush but quite exciting to think this major phase is nearing completion!

![[IMAGE]](http://www.darrylsgarage.com/912/912flord.jpg)

Entry: 10/16/06 - Most of the morning was spent driving down to Kent to pick-up four 80 lb. bags of 80-grit aluminum oxide blasting media and driving up to Everett to pick-up a few more cheap vise-grips for the big floorpan welding job from Harbor Freight Tools. Once I got back to work in the shop, the focus was on getting the remaining plug-weld flanges prepped for welding. Just about the time I was finishing the last flange and started on repairing the broken parking brake tube, that familiar sound of the UPS truck's horn honking alerted me to a delivery. YES!!! The Stoddards order arrived with the new parts I need to install in the center tunnel before I can commence with welding in the pans!!!

![[IMAGE]](http://www.darrylsgarage.com/912/912pbrk1.jpg)

Fixing the parking brake tube first required cleaning all the grease out of it so it wouldn't catch fire with the welding. It took 6 passes with clean cloth swabs soaked in carb cleaner, pulled thru like a gun cleaning patch on a length of wire. I wire brushed the area to be welded and discovered it had been brazed before so instead of MIG welding it, I got out the oxy/acetylene torch and added some more flux and brass to the cracked mounting bracket. It was a bit difficult brazing upside-down but I was able to form a nice drip that reinforced the cracked area and declared it done. I removed the old brake line, able to save the rubber plugs that run through the front and rear bulkheads and ran the new one without the rubber plugs until after welding is done. I was going to run the new speedometer cable but fear that I might damage it during the floorpan welding so it must wait. I finished by installing the new throttle rod bushings and the throttle rod. I do believe that everything is good-to-go for welding in the new rear floorpan in the morning!!!

![[IMAGE]](http://www.darrylsgarage.com/912/912pbrk2.jpg)

Entry: 10/17/06 - Today's work was interrupted with a call from the Honda dealership informing my wife that the new 2007 CR-V she had ordered to replace her car we totaled last month had arrived so we had to go take delivery. With the interruption, I was only able to get the rear pan about 95% welded-in and still need to weld the area at the rear edge of the center tunnel from the underside. The plug-welds went in quite cleanly and I'll only need to dress the ones visible from the outside of the car. The unibody rigidity of the rear section is amazingly drum-like and I'm anxious to see the additional improvement when I get the front pan welded in.

![[IMAGE]](http://www.darrylsgarage.com/912/912RFLR2.jpg)

I lost count at about the 100th plug-weld!

![[IMAGE]](http://www.darrylsgarage.com/912/912RFLR3.jpg)

Entry: 10/18/06 - Tonight the new floorpans are welded in with only a few seams on the bottom and around the pedal area to complete. Everything fit perfectly and with a bit of trimming and air hammer work up front, blended in with the original pan very nicely. The floors respond with a nice low thud when I drum on them with my fist.

![[IMAGE]](http://www.darrylsgarage.com/912/912florf.jpg)

The last step is fitting the small pressings on the inside torsion bar area that covers the still visible flexible heater tubing patch. The repair kit I bought from Stoddards for the area around the torsion bar tubes came with the sheetmetal pressing for that area so I'll be able to replicate all the details of the original. I have a lot of plug-welds to dress with my grinder all the way around that lower rockerpanel edge but it sure feels great to be nearing completion of this phase.

![[IMAGE]](http://www.darrylsgarage.com/912/912flore.jpg)

Entry: 10/19/06 - Today I completed all the remaining welds, the most significant of which was the weld at the floor of the center tunnel where it meets the rear bulkhead. The factory weld was a bead where the two sheets of steel lay on top of each other. I thought it would look most factory if I used my oxy/acetylene torch and steel rod, so that's how I proceeded. Here's how it looks all welded up and primed, just like the original did!

![[IMAGE]](http://www.darrylsgarage.com/912/912florh.jpg)

Once I put the welders away, it was time to start grinding plug welds. I was able to get the driver's side rockerpanel pinch weld seam completed and here's how it sits tonight. I'm going to be grinding for several days to get everything done but it sure makes me happy to see more sections coming to completion!

![[IMAGE]](http://www.darrylsgarage.com/912/912florg.jpg)

Entry: 10/20/06 - Today's task was taking the inner longitudinal channel patch panels, which came with the kit I purchased from Stoddards, and trimming them to fill the void I cut away to remove all the traces of rust. I wanted to make sure the circular indentation found on the originals was retained in the patch.

![[IMAGE]](http://www.darrylsgarage.com/912/912flori.jpg)

Tonight the patch panels have been snipped and formed down to size and are clamped in place ready for welding in the morning. I also have a small patch to weld into the driver's side rear corner of the floor bulkhead, which was rusted on one side but not the other. Once they are all welded in, I can give the entire area the "faux factory undercoating" treatment like I did around the torsion bars and move on to grinding more plug-welds. I was sore today from all the grinding I did yesterday... luckily I have the 4-post lift so all the grinding was at chest level instead of laying on my back on the ground! Guess I shouldn't bitch too much, eh? :^D Oh and yes, those round things on the banana arms in the following photo are plastic rattle-can lids... those brake hose retaining tangs are damn sharp and right about forehead high... can you say, "HEAD-ON, APPLY DIRECTLY TO THE FOREHEAD!" That and put the plastic caps on them so you only have that unpleasant experience only once!

![[IMAGE]](http://www.darrylsgarage.com/912/912florj.jpg)

Entry: 10/21/06 - Today's job was welding in the patch panels for behind and under the rear torsion bars. I wasn't completely happy with the left side so I re-worked it a bit to keep things perfectly symmetrical with the right one. I also welded in the small corner patch where the left rear floor bulkhead meets the longitudinal and floorpan panels. Once the welding was completed, I dressed the welds and blended in my "faux factory undercoating" to where I had left off on the left side, since I have already completed dressing the entire rockerpanel flange welds. You can see today's new plug-welds visible on the right side patch panel in the background of the following photo.

![[IMAGE]](http://www.darrylsgarage.com/912/912LLNG1.jpg)

Once the finger-tip "dabbed" 3M Ultrapro Autobody Sealant has dried, I'll be giving it 2-3 thick coats of Wurth high-build underseal as I've done on the other areas of the car. As you can see in the following photo, the merging of the seams for the floor, rear cabin floor bulkhead and longitudinal panel looks just like factory original. The thick coating of the 3M seam sealer replaces the nasty asphalt coating I scraped-off to prep for the welding. I also patched the undercoating on the torsion bar tube where some jack scrapes had rubbed through the original coating. With the overcoat of Wurth High-Build Underseal, this should blend back in nicely with the remaining factory original undercoating.

![[IMAGE]](http://www.darrylsgarage.com/912/912LLNG2.jpg)

Entry: 10/22/06 - Dressing the plug-welds on the entire right rockerpanel flange and the inner panel under the right torsion bar was the first task for the day. Once that task was completed, it was "faux factory undercoating" time for those areas.

![[IMAGE]](http://www.darrylsgarage.com/912/912RLNG1.jpg)

The patch was somewhat smaller on the right side so while not exactly a mirror image of the 3M Ultrapro Autobody Sealant application, all the same areas given the treatment as I did on the left side yesterday. I'll be removing the rear suspension banana arms again when I spray on the Wurth high-build underseal, so I can give the areas around their mounting brackets a thin coat to dress the area up. I would like to preserve as much of the original undercoating as possible so I'll be masking off large sections around the rear seat pans so the overspray doesn't mar their original appearance. I'll be dressing the welds visible inside the cabin, such as around the foot pedals and giving all the weld flanges a thick coat of 3M Seam Sealer as my next area of focus.

![[IMAGE]](http://www.darrylsgarage.com/912/912RLNG2.jpg)

Entry: 10/23/06 - Time to finish the "faux factory undercoating" on the rear longitudinal area. I removed both side's rear suspension banana arms plus the brake lines and pulled any wiring harness, fuel line and heating cables out of the retaining tabs so I could use my favorite purple "SuperClean" biodegradable degreaser and scalding hot water to prep the areas under them for a coat of Wurth high-build underseal. After masking off the areas I didn't want to spray with newspaper and aluminum foil, several thick coats were applied. I masked-off the floorpan because I'm planning on using anther Wurth undercoating product on them, which will form factory style drips with the help of gravity, something I can't do on the vertical surfaces that receive the "faux" treatment. Tonight the underseal is drying in the heat of two 500-watt halogen spotlights. I consider this area pretty much finished and ready for final installation of the suspension, speedometer cable, new seals and brake lines.

![[IMAGE]](http://www.darrylsgarage.com/912/912RFLR4.jpg)

Entry: 10/24/06 - Finishing the undercoating and performing final assembly of the rear suspension area was the goal for today. I gave the wheels and tires a thorough cleaning and bolted everything back into place with careful touch-up of painted parts that had been oversprayed or scraped. Once everything was back in I sprayed the entire area with clear high-temperature engine enamel to freshen-up the surfaces and make them shine. I started putting the new rubber control bellows on where they come through the rear center tunnel bulkhead, all but the speedometer cable. Suffice to say, I'm pretty stoked with how all this went back together and to have finally finished this section.

![[IMAGE]](http://www.darrylsgarage.com/912/912done2.jpg)

![[IMAGE]](http://www.darrylsgarage.com/912/912done3.jpg)

The last half of the day's labors went into grinding down all the welds on the bottom side of the front floorpan and dressing the seams with 3M Ultrapro Autobody Sealant. I textured the seam sealer with my "faux factory undercoating" fingertip dabbing method to even out the surfaces where the seams are lapped over each other. I'm ready to start with the inside floorpan work next, which will focus on dressing the welds up around the pedal area.

![[IMAGE]](http://www.darrylsgarage.com/912/912flork.jpg)

Entry: 10/26/06 - Preparing the interior floorpan for soundproofing was the focus of my efforts the last couple days. My first task was to grind all the welds, first with minimal dressing of the plug welds since they'll be hidden by seam sealer and the spray-on soundproofing. The welds around the pedal area were fully dressed to the point where the seam is not visible. A quick media blast of the rust scaled pedal cluster base and a test fit into the floorpan confirmed that none of the new welds interfered with the controls. Once the weld dressing was complete, I thoroughly vacuumed and blew the grinder dust out of all the recesses and gave the seams a liberal coat of SEM Rust Seal to stabilize the metal around the weld areas. After letting the SEM Rust Seal dry overnight, I prepped the entire floorpan for painting with a ScotchBrite pad soaked in DuPont KwikPrep 244S solvent. Once the KwikPrep dried, with the help of some compressed air, I brushed-on a thick coat of black Eastwood's Rust Encapsulator which, as you can see in the following photo, is in the process of drying with the help of two 500-watt halogen lights under the car which raises the surface temperature of the floorpan to about 80°. All the metal is now sealed with a waterproof (rustproof) barrier for the soundproofing material to be applied upon.

![[IMAGE]](http://www.darrylsgarage.com/912/912florl.jpg)

Entry: 10/28/06 - After a day of curing over the heat of two 500-watt halogen lamps, the thick coat of Eastwood's Rust Encapsulator had hardened enough for a liberal application of 3M Ultrapro Autobody Sealant to the weld seams.

![[IMAGE]](http://www.darrylsgarage.com/912/912florm.jpg)